Blades of Glory

Knives forged from stainless steel await a buff, polish, and handcrafted handle.

The rushing rapids of the Deerfield River greet me as I pull up to the Lamson & Goodnow cutlery factory in Shelburne Falls. The water, though, isn’t just a picturesque backdrop for the company’s campus of warehouses — it’s the lifeblood of the knife-making operation.

“The river has always powered this factory,” says president Brian Hayes, who explains that Lamson & Goodnow has been running on hydroelectricity since its founding in 1837. The oldest continuously operating knife manufacturer in the country, L & G has produced steel cutlery for everyone from Ulysses S. Grant to the latest generation of hot chefs. “We’re still using old-school methods, so [our cutlers] are doing it all by feel and by hand,” Hayes says.

And when he says old-school, he means it. On a walk through the warehouses with sales director Jeff Kostiuk, I spot several pieces of antique machinery that are used on a daily basis, such as a seesaw-style pipe cutter and an original rope-pulley elevator. The workers, who range in age from their early twenties to their sixties, stand before ancient, hand-engineered machines, grinding and polishing blades before sending them to the finishing rooms, where wooden handles are cut to size, fastened, and then hand-buffed to a glossy sheen.

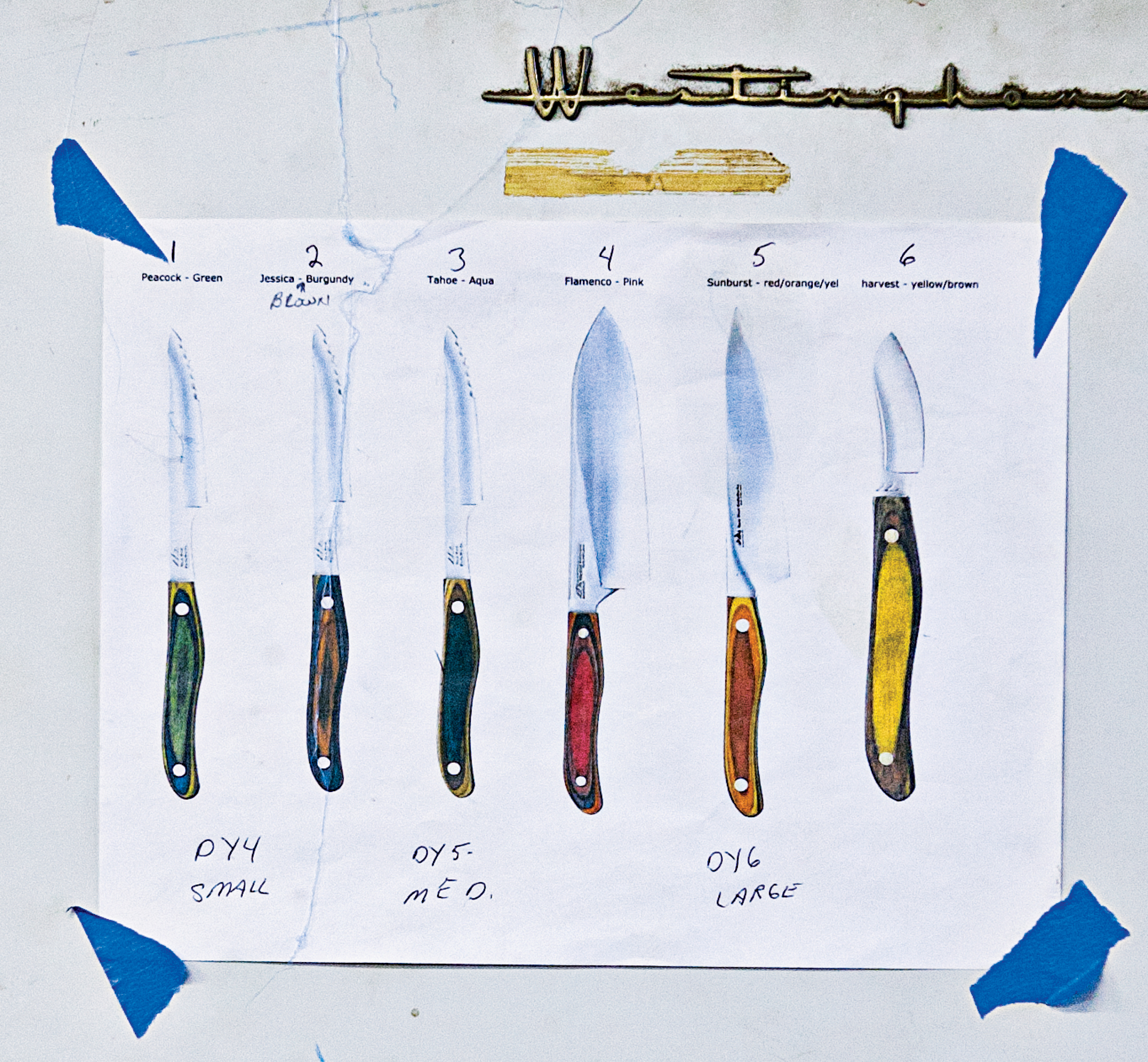

The knife edges are sharpened one final time by hand before they’re individually packed and shipped to order. We stop to watch one of the craftsmen as he gently softens a rainbow-colored handle made of “fusion wood” — layers of plywood that have been manually compressed. Kostiuk hands me two of the freshly polished knives. “There are minute differences in each one, since they’re each made individually,” he explains.

Attention to craftsmanship has always been a priority for L & G, from its early days making hay-cutting tools right up through today. Hayes won’t divulge which big-name brands he supplies, but he will say that if you’re buying from an American company that touts American-made kitchen knives, they’re probably being made in Shelburne Falls. L & G also produces its own line of cutlery, ranging from lightweight, laser-cut pieces (the massive laser is the factory’s only high-tech piece of machinery) to hefty hand-forged pieces that can sell for hundreds of dollars each. The company also does a healthy business in kitchen tools, from jumbo spatulas and potato mashers to serrated butter spreaders and cherry-handled barbecue tools.

L & G’s ingenuity isn’t the only thing that’s stayed the same through the years. “We’ve always inherently been a green manufacturer. We create our own energy with the power of the river,” Hayes says. Other environment-friendly practices at L & G include using steel that is 98 percent post-consumer recycled; turning wood trimmings into sawdust that is used at a local pig farm; buying only Massachusetts-grown lumber; and making steel wool out of steel scraps.

Hayes says his company’s ability “to take a piece of steel and within a day produce a gorgeous knife, all from materials we get right here — that you can then pass down — is how we keep America strong.”

Handles are carved from materials like acrylic, walnut, and composite wood.

Craftsmen apply each component by hand, including the metal rivets.

The finished blades receive Lamson’s signature etching before they’re sharpened.

L & G has operated on this site beside the Deerfield River since 1837.

Some of the company’s machinery has been cobbled together to perform very precise knife-building duties.

A run of “fusion wood” handles, which have minute color variations.

Blades get a final polish before they’re packaged and shipped around the world.