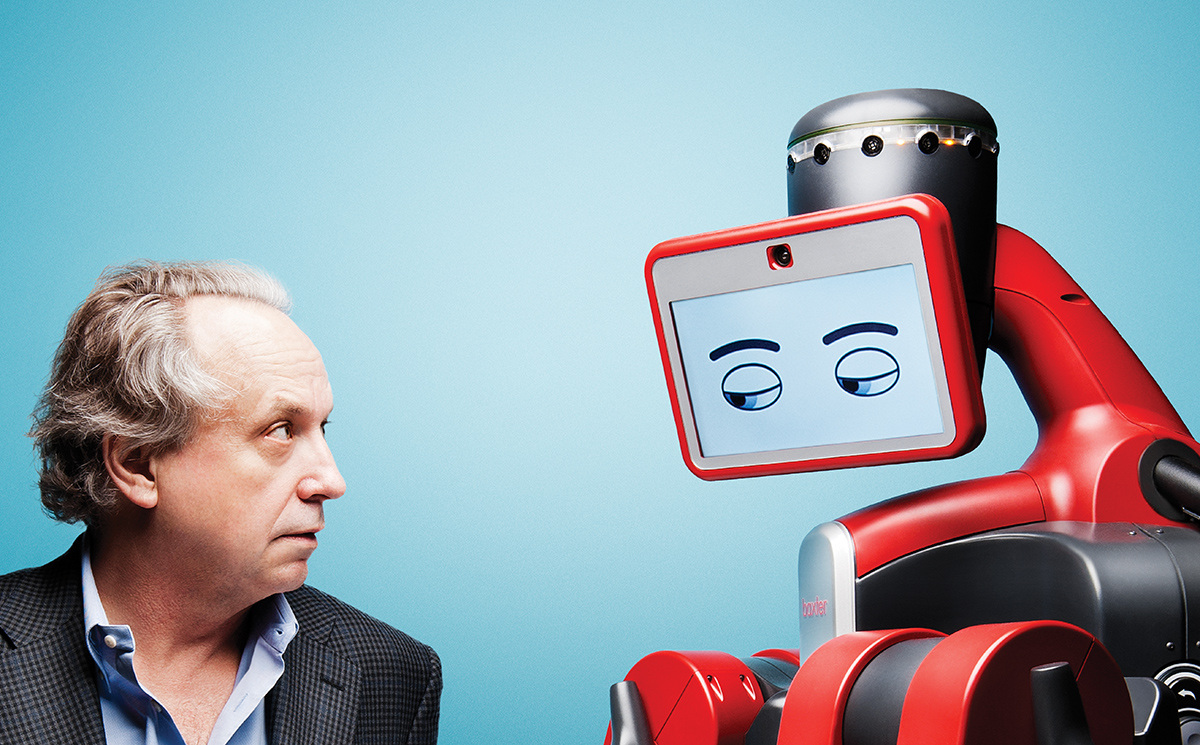

Machine Man: Rodney Brooks

Baxter, Rodney Brooks’s latest robot, regards its maker with expressive LCD eyes. Photograph by Webb Chappell.

The things I learn about Rodney Brooks before I first meet him make me nervous. I know he was strange from the start. That at age four he was called “the professor.” That at 12, he rigged an electronic ticktacktoe game together out of scrap metal, switches, wires, and light bulbs. That, to this day, the movie 2001: A Space Odyssey brings him to tears.

And that when his daughter Alice asked him for a Barbie, he instead bought her a saw and told her to make her own toys.

I’ve also seen Brooks on film. He was the scraggly haired, wild-eyed techno-topian in Cambridge director Errol Morris’s 1997 documentary Fast, Cheap & Out of Control—the one who claimed that his goal in robotics was “to understand life by building something lifelike.” In a series called Big Thinkers for the now-defunct TechTV, Brooks declared, “Anything that’s living is a machine. I’m a machine; my children are machines. I can step back and see them as being a bag of skin full of biomolecules that are interacting according to some laws.”

Brooks has come a long way—and built a lot of robots—since then. He spent a decade as the director of the Artificial Intelligence Lab at MIT, where he was one of the first scientists to give robots the ability to process data on their own. He also cofounded iRobot, maker of the floor-cleaning Roomba and the roadside-bomb-defusing PackBot. And now, with Rethink Robotics, a Fort Point–based company Brooks founded in 2008, he’s making an industrial robot named Baxter. In talks available online, I’ve seen him proselytizing about the oncoming robot revolution with varying degrees of ferocity. Most recently, he’s been vehemently warning us that in the future, we might not have enough robots to go around.

All of which explains why, upon entering the offices of Rethink Robotics, I’m concerned that this guy might be, as they say in his native Australia, a complete nutter. Though Brooks is the company’s founder, he works from a cubicle in the far recesses of Rethink’s space. Brooks greets me by regarding his excessively cluttered desk as if for the first time, and then asking, “Where did this mess come from? Who put all these things here?” For a brief moment, I think he’s serious.

But as we chat further, Brooks, 59, is calm and confident, a demeanor more befitting the man who some consider the father of modern robotics than the character in Morris’s film. He’s also the father of three grown biological children and one stepdaughter. So I ask him, these many years later, to describe the parallels between conceiving children and conceiving robots. But unlike the Brooks in Morris’s film, he does not offer a lecture on the definition of life. Instead, he laughs.

“Yeah,” Brooks says, “everyone wants to make that comparison. But, nah. That’s too stretchy. Reporters would often come to my lab at MIT and say to me, ‘Oh, you’re making these robots because you don’t have a womb and you can’t have children.’ I’d say, ‘Oh yeah? So you see all these women graduate students I have in my lab? Is that why they’re here, too? Because they don’t have wombs?’”

He throws both hands in the air and shakes them in mock surrender. “Okay. Yes. I will admit it. I don’t have a womb. But that’s as far as I will go.”

He thinks about it another second and reconsiders. “None of my robots have ever shat all over the floor or vomited in my mouth,” he says. “But my kids have.”

That may be so, but Brooks has worked to make many of his robots lifelike, and has given many human names. He has created a Norman and an Allen and a Herbert and a Polly. Under his watch, his students created a Kismet and a Cog, and iRobot created My Real Baby, all of which had faces and talked to you. His latest creation, Baxter—the flagship of Rethink Robotics— is a tablet-faced robot with big, expressive, cartoon eyes and two red-and-black plastic arms. It doesn’t look anything like the faceless industrial robots that now dominate global manufacturing—and that’s on purpose.

Unlike those machines, which need to be walled off from human workers because they can’t detect when something living is in their way, Baxter is an easily reprogrammed, 165-pound robot equipped with sonar and cameras that help it adapt to a changing environment. Brooks explains that he gave Baxter human qualities specifically so it could integrate more easily into the human world. For example, Baxter’s LCD eyes will look at the spot where it’s about to reach, making its movements, from a human perspective, more predictable. “If you want a machine to be able to interact with people,” Brooks says, “it better not do things that are surprising to people.” Brooks likes to demonstrate his machine’s sensitivity by sticking his head into the path of one of Baxter’s moving arms. As soon as Baxter gets close to its creator, the arm stops. “It’s safe,” Brooks says. “It won’t hurt you.”

But Baxter does pose one potential threat to people: At a cost of $25,000, it’s significantly cheaper than a typical industrial robot, and cheaper than a lot of factory workers as well. Combined with the fact that Baxter is also easy to train—you just push its arms around and punch a couple of buttons and it does the rest—Brooks’s latest creation could put a lot of humans out of work.

long before there was baxter, there was Norman. Built with scrap metal, cheap circuits, and a little mathematical intuition, Norman could follow a flashlight beam or scurry around the room on its own, Roomba-style. Brooks created Norman 39 years ago when he was a kid in Glenelg, Australia, a beachside suburb of Adelaide—450 miles west of Melbourne, 1,700 miles east of Perth, and far, far away from the rest of the world. “I come from a time warp,” Brooks says. “We were so isolated that we were almost from another era. Milk was still delivered by horse-drawn cart.”

By his own admission, Brooks wasn’t a normal kid. He’d go to downtown Adelaide just to stare at a local bank’s big IBM mainframe computer. “I won some genetic lottery,” he says. “I always happened to be strangely good at mathematics in my head. I just popped out weird.”

At 12, he made that electronic ticktacktoe game with a technical limitation that frustrated adults: The game always made the first move, and that move was always the center square. Though the game could be beat, adults took the glitch to mean that it had been designed to cheat them. “Ai yai yai,” Brooks says. “I had very little patience for adults. I considered them idiots at the time.”

When Brooks wasn’t tinkering with circuits in the backyard shed, he was blowing things up around the neighborhood. “You could get sodium chlorate in weed killer and you’d mix that with sugar,” he says, his gray hair flaring out from the sides of his head, made worse by his habit of running both hands through it while he speaks. “It’s dangerous and makes big explosions.”

After getting bachelor’s and master’s degrees in mathematics from Flinders University, in Adelaide, by 1977, he left Australia for the first time, and in 1981 earned a Ph.D. in computer science at Stanford. He married his first wife (currently an information systems lecturer at Suffolk University), and then headed east, eventually landing a teaching job in MIT’s Artificial Intelligence Lab.

In the summer of 1985, while visiting his first wife’s family in a Thailand village, Brooks found himself house-bound: He didn’t speak Thai, they didn’t speak English, and there was some concern for the young professor’s safety. Without much to do, Brooks sat and thought and watched mosquitoes buzz around him. Which led him to wonder how it was that mosquitoes could move so efficiently even though they were such simple creatures, with only a few-hundred-thousand neurons? (Human brains, by contrast, have about 86 billion neurons.) The robots being created in labs like Brooks’s at MIT utilized vast amounts of computational power, yet they were still dumber than insects.

At the time, robots were designed with sensors that fed information into a transmitter, which then fed that information into a mainframe computer, which then processed the data and figured out what the robot needed to do, then sent a command back through the transmitter to the robot, which executed the command. Needless to say, those robots were really slow. Throw a few obstacles in their way, and the robots could take hours to move a few meters.

Brooks’s revolutionary idea, which he sketched out on paper at his in-laws’ house, was to simplify. Don’t build a map of the robot’s world and dump all that data into its microprocessors just to keep it from running into a wall. Instead, give the robot one rule: “Move your legs,” for instance. Then give it another: “Don’t run into stuff.” Then give it something complicated, like, “Explore.” With Brooks’s simplified approach, the robot wouldn’t need to know everything about the world before starting out. It would do simple stuff in simple ways, just like a mosquito.

Brooks says that his contemporaries considered his idea naive. “They thought we were playing with toys,” he says of the insectlike robots he subsequently built in the MIT lab. Well, they did look like toys. And yet one of those “toys,” built in 1988, was perhaps the most important robot ever made. It had six legs and could walk, climb, and move at a speed few other robots had reached up to that point. Its name was Genghis.

Brooks talks about Genghis like a guy talking about his high school football glory days. His eyes widen to almost Baxterlike cartoonishness, his Australian accent getting more pronounced as he raises his voice. Genghis was radical because it was endowed with basic artificial intelligence so it could adapt to its environment. That tiny design enhancement sparked a programming revolution—nearly all robots are now built that way—which is why Genghis spent a decade on display at the Smithsonian’s National Air and Space Museum, not far from the Apollo 11 command module and Orville and Wilbur Wright’s Flyer.

The impact of Brooks’s breakthrough—which made robots ever cheaper, smarter, and easier to produce—has been profound. In hospitals, robots made by Aethon shuttle bed sheets to and from laundry facilities. In Amazon warehouses, robots made by Kiva Systems ferry shelves full of products to and from the people who prepare them for shipping. In Afghanistan, iRobot’s PackBot scuttles around disposing of bombs, rendering The Hurt Locker’s life-risking approach obsolete.

While all of these robots were influenced by Genghis, they don’t look like insects. Nor do they look humanoid, like Baxter. And many of them fail to give humans the cues needed to interact with them. That’s a fundamental concept missing from Google’s self-driving, robotic car, for example, a shortcoming that infuriates Brooks. You can’t make eye contact with it, so how do you know that it sees you? “You can make the assumption that most human drivers are not out to kill pedestrians,” Brooks says. “Well, maybe in some parts of Boston they are. But with a person at the wheel who you can see, you behave accordingly. With the robotic car, how do you know what assumption to make?”

Brooks cofounded the bedford-based iRobot in 1990, and his motivation, he explains, had something to do with vanity: “My thoughts on my self-image at the time was that I didn’t really want to be remembered for building insects.” Then he pauses for a moment and laughs. “But after that I started building vacuum-cleaning robots. And now there is a research group using Baxter to open stool samples. So now it’s shit-handling robots. I think maybe I should have quit while I was ahead. You know, that’s something no one ever says: ‘I hope my kid grows up to open stool samples.’”

The Roomba robotic vacuum didn’t hit the market until 2002, and in the meantime, Brooks married his second wife, MIT theater professor Janet Sonenberg, and raised his four children: Alice, 26, Andrew, 29, and Matthew, 31 (whom he’d had with his first wife), plus Anna Rothschild, 28, Sonenberg’s daughter. All of his biological kids went to Lincoln-Sudbury High, and two graduated from MIT. Alice has degrees from both MIT and Stanford, and recently founded a startup company called Roominate, which makes engineering toys for girls. “She manufactures in China!” Brooks shouts. “My own flesh and blood manufactures in China! Kids. They never go the way you want them to.”

Photograph by Webb Chappell

Alice says her father didn’t help her finance her California-based company, even though, as Brooks himself will admit, iRobot has made him rich. “I wanted to do it independently of asking him for money,” she says. “But I learned a lot from him being in an entrepreneurial business. Seeing the example that anything is possible was a huge influence.”

Throughout the ’90s, Brooks kept his MIT professorship while working with the iRobot team to develop Roomba. He says his main contribution was hunting all over China trying to find cheap and tiny microprocessors. Then, in the final phase of development, Roomba’s engineers realized that those diminutive microchips couldn’t run the complex software they’d developed. Adding more memory to the processor would have set the project back by months. “So I told Rod about it,” says Colin Angle, Brooks’s former student and a cofounder of iRobot, “and Rod said, ‘Oh, I’m flying to Japan tomorrow. I’ll rewrite the compiler and it’ll be okay.’ Now, writing a compiler is one of the most challenging software tasks that exists. But he takes off, lands 16 hours later in Narita airport, and sure enough, he emailed an executable file that was 35 percent smaller and ran perfectly.”

Angle says Brooks did stuff like that all the time at iRobot: He was “the drive-by shooter of productivity,” Angle says. “Anything that needed doing, Rod would do it,” agrees Helen Greiner, an MIT graduate who also helped found the company. “But he wasn’t someone you could task. He’s not the guy who is going to join the team and be involved in all the discussions. He’s the guy who comes in and changes the paradigm.”

Brooks started thinking about industrial robots around 2005, in part because of all the time he’d spent in China on iRobot’s behalf. While there, he’d seen tens of thousands of workers performing mundane, repetitive tasks, and wondered why machines weren’t being used for those jobs instead. In some cases, robots weren’t adaptable enough to perform the tasks that people were hired to do. In other cases, the answer was simple economics: Unskilled people were still cheaper than robots. One estimate suggests that, over its lifetime, a typical industrial robot could cost a company $500,000, due to servicing and reprogramming costs. But Brooks wasn’t just concerned about people doing mind-numbing tasks. He was also fiercely driven by a desire to help American manufacturers compete globally. Brooks’s theory was that cheap, adaptable machines would enable them to produce more goods more affordably than even China’s low-cost labor force, thus heralding a domestic economic renaissance.

He floated the idea with iRobot’s board of directors, but they weren’t interested in investing in a new, automated workforce. Their consumer goods were selling well, and the high investment costs of developing tools for a different market didn’t make economic sense. “Rod was completely enamored, obsessed, and inspired,” Angle says. “His idea was that you could build an extremely low-cost robot arm and change the world with that. But we knew that was a bridge too far for iRobot at the time.”

So in 2008, Brooks took a leave from his MIT professorship, which he’d held onto throughout his iRobot days, and wound down his relationship with iRobot to launch Rethink. He had signed a noncompete agreement, but kept his stock and options—by 2011, his last year on iRobot’s board, they were worth as much as $20 million. In addition, iRobot received a percentage of ownership in Rethink in return for letting Brooks leave amicably. “Having had a successful exit with iRobot,” Brooks says, “I could afford to grease the skids personally.”

The efficiency of machine over human has long prompted factory owners to automate so they can compete in the global market, and at a cost of $25,000, Baxter is a great deal. Since Baxter has an estimated lifespan of at least 6,500 hours, its pricing works out to about $4 an hour, at a time when labor costs are rising in most of the world. Chinese manufacturing labor costs tripled between 2002 and 2009; American manufacturing jobs pay an average of $35.53 an hour; and Taiwanese pay $9.34 an hour. In Mexico, those jobs pay $6.48. You’d have to go to the Philippines, where a factory worker makes little more than $2 an hour, to find people working at wages competitive with Baxter.

But with machines like Baxter rapidly coming to the market, manufacturing jobs may disappear faster than workers can retrain for the new automated economy. That’s what MIT scholars Erik Brynjolfsson and Andrew McAfee warn in their 2014 book The Second Machine Age: “Technological progress is going to leave behind some people, perhaps even a lot of people, as it races ahead. There’s never been a worse time to be a worker with only ‘ordinary’ skills and abilities to offer, because computers, robots, and other digital technologies are acquiring these skills and abilities at an extraordinary rate.”

Brooks has heard that kind of criticism before. Actually, he’s heard much worse. Brooks and Baxter have appeared everywhere from Wired to 60 Minutes since Baxter’s launch, and some of the stories on Brooks’s latest robot have warned of the dangers from “our new robot overlords.” It’s a topic that seems to exasperate Brooks when I bring it up. “Are those ‘terrible’ machines really putting those people out of work?” Brooks asks. “Or are they getting rid of a really dull job that we shouldn’t be torturing people with? Individuals who have done that job for a long time and are settled into it may feel it’s not good [to eliminate it], but on the other hand, as a species, shouldn’t we get rid of jobs that are that dull and are mind-deadening? People don’t say, ‘I just had a kid and I hope it turns out to be a factory worker.’”

In fact, a 2011 report by Deloitte and the Manufacturing Institute supports Brooks’s assertion that Americans, at least, don’t want those jobs. According to the report, U.S. factories are being handicapped by a labor shortage, exacerbated by the “stubbornly poor perception of manufacturing jobs among younger workers…among 18-[to-]24-year-olds, manufacturing ranks dead last among industries in which they would choose to start their careers.” Therefore, it continued, a significant number of American manufacturing jobs (up to 600,000 by one estimate) are going unfilled, negatively affecting “critical functions like new product development, implementation of new technologies, or attaining productivity targets.”

Which is why Brynjolfsson and McAfee concede that, in the short run, Baxter could actually increase demand for a skilled manufacturing workforce. Brynjolfsson tells me that Baxter is “an example of what we call racing with machines instead of racing against machines. Technologies like this will help bring manufacturing back to the U.S. and other high-wage countries.” Indeed, the manufacturing report notes that with increased automation and the prevailing factory-work-averse culture, “access to a highly skilled, flexible workforce is the most important factor in [manufacturers’] effectiveness.”

Yet, as Rethink and third-party programmers increase Baxter’s capabilities, the robot could replace a broader range of jobs, possibly beyond the factory and right into your local Starbucks. Baxter has made a cup of coffee and poured a drink before. But Brooks has said repeatedly that the robot isn’t dexterous or adaptable enough—yet—to do the many tasks that even a fast-food worker might perform in a given day. This summer, with a Rethink software update, Baxter’s speed and accuracy doubled. “We’ve had a dramatic improvement in performance this year,” says Paul Maeder, a founding partner of the Boston-based Highland Capital Partners, one of the venture capital firms that has invested in Rethink. “Now our sales are starting to explode.”

All of this alarms Martin Ford, a Silicon Valley–based futurist and the author of The Lights in the Tunnel: Automation, Accelerating Technology and the Economy of the Future. “As I think about the robot revolution,” Ford tells me, “I worry a lot more about robots in fast food, robots in the retail store, than I do about manufacturing. The service sector is where 90 percent of the employment in the United States is.” Ford argues that jobs like flipping burgers and making coffee drinks have been a godsend for a shrinking middle class: “Think of all the college graduates who take jobs as cashiers or baristas before they find salaried work,” he has said. “If those jobs were to vanish, those workers would be forced to file for unemployment instead.”

And if Chinese companies decide to employ Baxter, too? Maeder confirms that Rethink has had some interest from Asia. Introducing Baxter to China could “potentially threaten millions of jobs in China and other emerging countries,” Ford says.

“The point is not for people to keep busy,” Maeder says. “The point is you can only get a higher standard of living by doing higher-skilled jobs that other people can’t do. The Chinese get that.”

Several weeks after our initial conversation in Rethink’s offices, Brooks meets with me again to discuss worries about robot armies destroying jobs. We’re at Flour Bakery in Fort Point, only a few blocks from the space Rethink leases in a former manufacturing plant that dates to the late 1800s. There’s still a giant brick smokestack outside that office; left as a nostalgic nod to the area’s industrial past, it’s now bedecked with cell-phone transmitters.

Sitting on the patio and drinking an espresso, Brooks admits that “in all new technologies, there is some disruption.” He then tells a story about his father, a technician who worked on phone systems. When Brooks was growing up, if you wanted to call from one Australian state to another, you had to book the call with an operator two days in advance. “Then there was this newfangled stuff they came out with called subscriber trunk dialing,” he says. “STD. That was before STD meant something else. With that you could dial your own interstate call. My father was aghast at that. ‘Why do we need that stuff?’ he’d say. But we did. We all do want the ease of technology. But it did displace those phone operators.”

Brooks then counters the critics with a dire warning of his own: An oncoming “ demographic inversion” will leave us with fewer people to do all kinds of jobs. In the presentations he makes around the world “evangelizing” about the future of robotics, Brooks shows slides based on a 2010 United Nations study: In 2050, the percentage of working-age people in the U.S. will fall from 80 percent today to 69 percent. In China, where Ford thinks perhaps millions of jobs could be threatened by Baxterlike bots, it’s more dramatic. Eighty-seven percent of that country’s population is now of working age; in 2050, it’s projected to be just 67 percent. Europe’s working-age population is projected to decline from 77 percent to 64 percent.

That’s why Brooks isn’t worried about robots taking away jobs in the U.S. or abroad, but is instead worried we won’t have enough robots to pick up the slack.

Brooks is also worried about his own advancing age. This past summer he returned to Australia to visit his mother, now a widow, who lives in a retirement home in Adelaide. As he was driving around the city in his rental car, Brooks tuned the radio to a program called The 100 Classic Albums That Changed Your Life. Number 19 was playing: AC/DC’s T.N.T., an album that came out December 1, 1975, less than a month before Brooks’s 21st birthday. Back then Brooks had a full head of brown hair that came down to his shoulders. “So an advertisement comes on during this program,” Brooks says. “It says, ‘Finding a place to live as you get older is going to be difficult. You should be thinking about your end of life.’”

His jaw drops open for comic effect. “Uh-oh. The 100 Classic Albums That Changed Your Life audience is supposed to be thinking about the end of life? That’s where we are now?”

This, incidentally, is the fourth time he’s referred to his advancing age during our chats. It’s clearly something that’s on his mind. During a TED talk he gave last year in Long Beach, California, with a Baxter operating on a mock assembly line behind him, Brooks told the audience that “robotics gives people a chance to have dignity as they get older.” With robots, he said, the elderly “won’t have to rely on people that are getting scarcer to help them.” By “elderly,” he meant, in part, himself. Brooks thinks Baxter could be one of those eldercare robots if researchers can find ways to make him useful in the home.

That’s not something Rethink is working on, but Brooks hopes some academics might. Of the several hundred Baxters that have been sold, many were purchased by academic institutions. At RPI, they’re using Baxter to act as a robotic body for a quadriplegic. At other universities they’re studying ways to make Baxter’s hands more adept. For all their advances, robotic hands are still very basic pinchers and grippers. “To get the grand vision to happen, you’ve got to have a lot of people doing research,” Brooks says. “So maybe with the research robots that are out there, people will come up with ways to use them to take care of the elderly. And that can help me someday. Because, you know what? I’m heading in that direction.”

Machine Menagerie

Twenty-five years of Rodney Brooks–influenced robots.