MIT Creates Giant LEGO-like Blocks That Can Be Used to Make Airplane Parts

Sure, people can make life-sized replicas of Batman and Robin, or small versions of city skyscrapers using LEGOs. But scientists and researchers out of MIT have upped the ante, and created a way for designers and manufacturers to create real-life structures using building blocks that snap together much like the childhood toys.

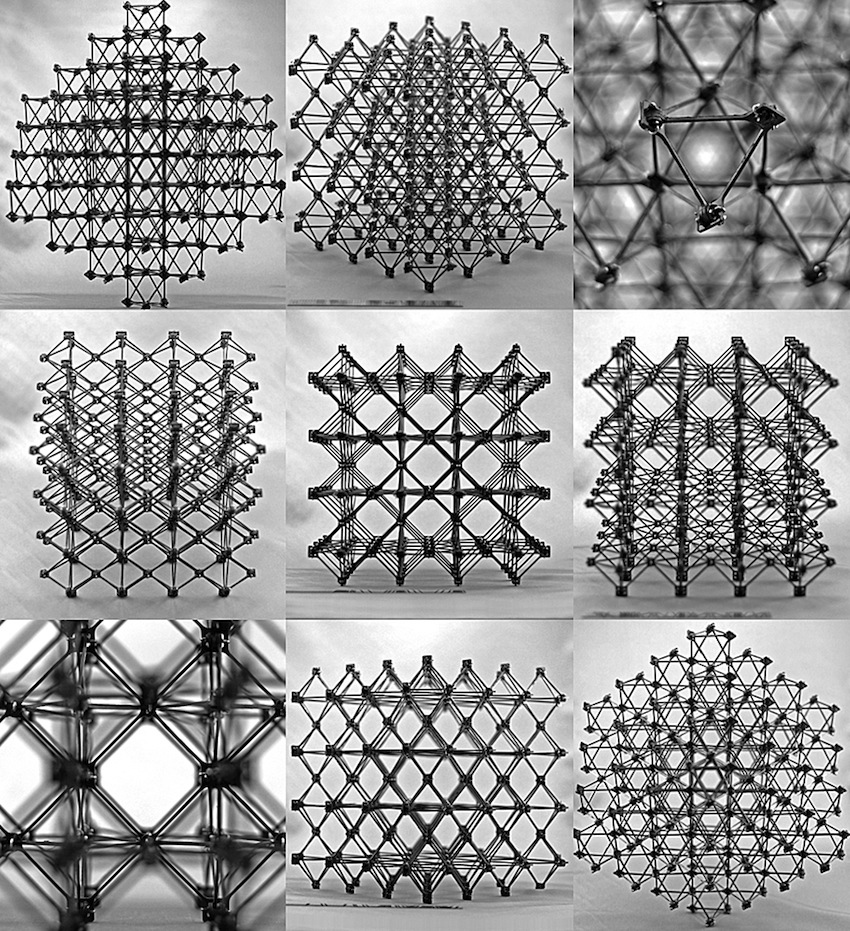

According to MIT News, postdoc student Kenneth Cheung and Neil Gershenfeld, director of MIT’s Center for Bits and Atoms, said the new material— which they describe as being like “chain mail,” made from tiny, identical, interlocking parts— could change the way large structures like airplanes and dam levees are built.

The parts, based on a novel geometry that Cheung developed with Gershenfeld, form a structure that is 10 times stiffer for a given weight than existing ultralight materials. But this new structure can also be disassembled and reassembled easily — such as to repair damage, or to recycle the parts into a different configuration.

Each individual part for a specific structure can be mass-produced using a robotic method of engineering and assembly that Cheung and Gershenfeld are currently developing.

According to MIT, the project encompasses three main parts of field research, including fiber composites, cellular materials, and additive manufacturing, such as 3-D printing, “where structures are built by depositing rather than removing material.”

The concept for the inter-locking material was born out of an interest to see if it was possible to 3-D print materials in order to create an airplane. “This satisfies the spirit of the question,” Gershenfeld told MIT. “But it’s assembled rather than printed.”

The team of engineers are developing an assembler robot that can crawl over the surface of a growing structure, adding pieces one by one to a project being built.

Besides Gershenfeld and Cheung, the project included MIT undergraduate Joseph Kim and alumna Sarah Hovsepian—now at NASA’s Ames Research Center. The work was supported by the Defense Advanced Research Projects Agency and the sponsors of the Center for Bits and Atoms, with Spirit Aerosystems collaborating on the composite development.

There work will be published in the form of a paper in an upcoming issue of the journal Science.