Peek Inside Massachusetts’ Newest Billion-Dollar Business: Pot Gummies

Gulp! You’ve just swallowed a pot gummy and are ready to get stoned when you ask yourself: Where does this thing even come from? Don’t sweat it—take an inside peek at one THC-infused candy’s journey, from seed all the way to sale.

The secret recipe for Coast Cannabis’s fruity gummies? Organic and all-natural ingredients (and, of course, 5 milligrams of the good stuff). / Photo by Bruce Peterson

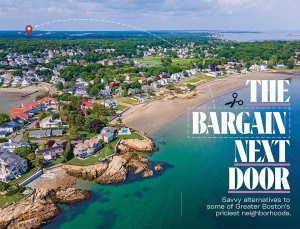

Cruise down any highway in the state these days, and you’ll notice one thing: The legalized weed business is booming. Nearly every mile, billboards advertising recreational dispensaries—filled with everything from pre-rolls to THC-laced ice cream—pepper the landscape, literal signs of a complex industry involving multiple supply chains and a thicket of regulations denser than a cannabis-filled greenhouse. And it’s growing bigger by the day. Store owners are fighting for market share, offering perks like home-delivery options to their customers. Operators are infusing THC into whatever they can, from candy bars and hot cocoa mix to olive oil and seltzer. And shoppers are still practically running to dispensaries for the chance to throw down their debit cards and take the latest product home to sip, taste, or toke. It’s safe to say that more Bay Staters than ever are getting high—in one form or another—on the region’s newest and most popular cash crop.

Take the tangerine-flavored gummies made by Coast Cannabis Co., a Wareham-based outfit founded by spouses Angela Brown and Brian Cusick. Far from the stanky pot brownies you might recall from college parties, these sweet little edibles must go through a long, multistep process before they can be purchased at a shop such as Pure Oasis in Dorchester.

It all starts with a seed at one of several locally based cultivation experts, including the Pass in Sheffield. From there, the marijuana is grown outdoors, indoors, and in a greenhouse, then harvested, dried, and transported in locked-down containers to Coast’s lab and kitchen, where the cannabinoids (the stuff that makes you feel oh-so-good) are extracted from the plant and finally transformed into delicious little gummies. The candies’ last stop before making it into the hands of eager buyers is one of around 85 stores, from P-town to Pittsfield, where they’re sold exclusively in-state (all cannabis products in Massachusetts must be grown and produced here).

It’s a story of high ambitions, and even higher stakes—one that we wanted to see with our own eyes. The result is a rare glimpse into the fertile soul of Massachusetts’ newest billion-dollar business.

Photo by Pat Piasecki

At the Pass’s outdoor grow operation, cultivation director Pete Steimer gets ready for “Croptober,” a.k.a. harvest season, by inspecting the cannabis plants growing among the 40,000-square-foot canopy.

Photo by Pat Piasecki

The Pass also operates a 5,800-square-foot greenhouse where cannabis is grown year round.

Photo by Pat Piasecki

Wearing nitrile gloves, a hairnet, and protective glasses to adhere to the facility’s strict sanitation protocols, Steimer assesses the buds and overall plant health of the Orange Cake strain.

Photo by Pat Piasecki

Once the plants are defoliated of the larger fan leaves, the flowers are cut and hung in a large climate-controlled shipping container to dry.

Photo by Pat Piasecki

The finished product.

Photo by Pat Piasecki

One of the first steps at Coast Cannabis’s production facility is grinding down the raw flower to create more surface area for the extraction process.

Photo by Pat Piasecki

Post-extraction, chemists distill the full-spectrum cannabis oil to isolate the THC and other cannabinoids and remove any undesirable compounds.

Photo by Pat Piasecki

Because Massachusetts requires that edibles contain no more than 5 milligrams of THC per serving, the distilled cannabis oil must be independently lab-tested and then precisely measured before it’s added to the organic sugar, gelatin, and other ingredients.

Photo by Pat Piasecki

The cooking process for the gummies.

Photo by Pat Piasecki

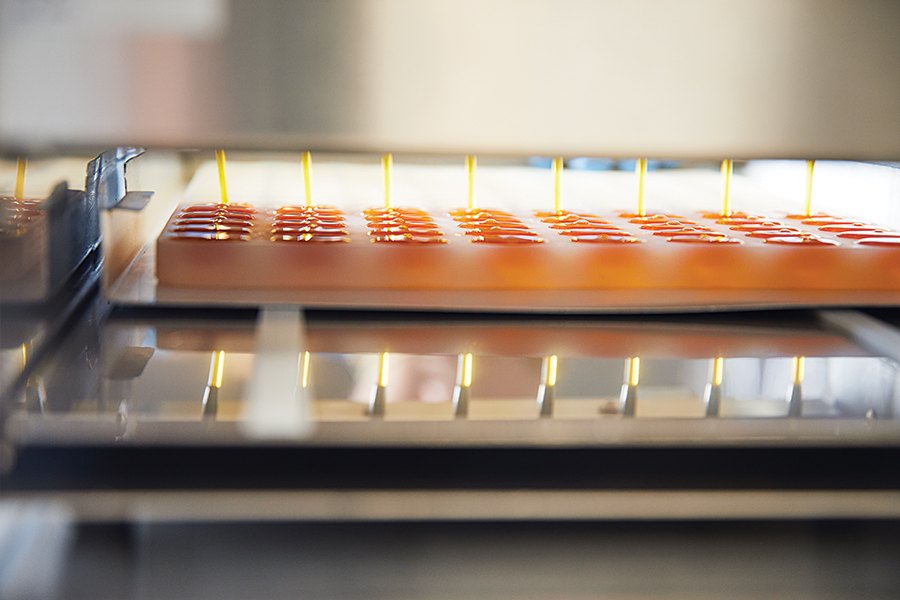

A metered depositor drops the liquid into gummy molds that hold 3.5 grams, ensuring proper dosing.

Photo by Pat Piasecki

After the product is cooled and sealed with an organic coating for freshness, it’s placed into bins for the quality-control process.

Photo by Pat Piasecki

The production team uses ice-cube trays to precisely count the 20 gummies that go into each bag.

Photo by Pat Piasecki

The finished product is sold to a customer at Pure Oasis in Dorchester, completing the seed-to-sale process.